Contributed by Scott Stamper, Environmental Specialist, PPM Consultants

Contributed by Scott Stamper, Environmental Specialist, PPM Consultants

In 2005, President George W Bush signed into law the Energy Policy Act. This Energy Policy Act, though not a change to EPA’s Underground Storage Tank (UST) Rules, was the first major revision that required states to modify their regulations for underground storage tanks since the original regulation that went into effect in 1988. This act also strengthened safety and environmental protections of the underground storage tank systems operating across the country. One of the requirements of the 2005 Energy Policy Act was establishing annual inspections of your UST system. In 2015 EPA revised their original 1988 regulations to include the annual inspections as well as many other new testing and inspection requirements, such as the 30-day walk through inspections. In this article, we will focus mainly on the annual requirements of a walkthrough inspection.

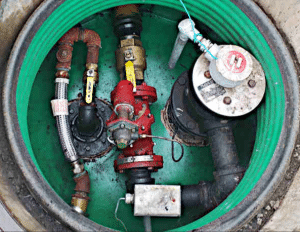

The current federal regulations (to be carried out by each state) requires all sumps (submersible turbine pump sumps often referred as STP Sumps and under dispenser containment sumps often referred as UDC Sumps), sump areas, and any hand-held release detection equipment you might use be inspected on an annual basis.

For UST systems installed BEFORE December 20, 2008, you will visually check the sumps and equipment inside for any damage, leaks, or releases into the environment. Water is permitted inside these sumps if metal parts of the UST system inside are cathodically protected. Cathodic protection prevents metal parts from corroding when in contact with soil or water. However, if your UST system installed before December 20, 2008, has double walled piping and utilizes interstitial monitoring for the primary means of release detection, the sumps MUST remain dry.

For UST systems installed BEFORE December 20, 2008, you will visually check the sumps and equipment inside for any damage, leaks, or releases into the environment. Water is permitted inside these sumps if metal parts of the UST system inside are cathodically protected. Cathodic protection prevents metal parts from corroding when in contact with soil or water. However, if your UST system installed before December 20, 2008, has double walled piping and utilizes interstitial monitoring for the primary means of release detection, the sumps MUST remain dry.

Some UST systems not using interstitial monitoring for leak detection, typically sites that are older, may not have sumps to house the STP or product piping below the fuel dispenser. For such UST systems, you must visually check the sump areas for damage to equipment, for leaks to the environment, and for cathodic protection of metal parts. Visually inspecting for leaks at a UST system without containment sumps is critical. All releases of these UST systems are immediately released into the environment because there is no containment area to collect the release.

For UST systems installed AFTER December 20, 2008, you will visually check all containment sumps and equipment inside the sumps. These sumps MUST remain dry because they are required to be used for interstitial monitoring. You must also visually check the sumps for leaks and releases to the environment. If water is discovered in any sump (STP or UDC), it must immediately be removed.

Hand-held release detection is also required to be inspected annually. Examples of hand-held release detection equipment include water bailers, vapor detecting monitors, and fuel gauge sticks. Water bailers are used at sites with release detection device (RDD) wells to collect water to visually inspect for the presence of free product in the well. Vapor detecting monitors are used at sites with RDD wells that monitor for the presence of hydrocarbon vapors. Fuel gauge sticks are sometimes used at sites that manually stick tanks to gather fuel level information when using Statistical Inventory Reconciliation (SIR) or manual tank gauging for their release detection. The more prevalent and modern method is for this date to be maintained using the automatic tank gauge probe sending information to the console (ie – Veeder Root TLS 350).

UST regulations also require other parts of the UST system to be tested annually. Although these annual tests are not required to be performed on the same day as the annual walkthrough inspection, it is a good idea these parts are tested on the same day as annual walkthrough inspection. As mentioned above, all ATG probes used for leak detection purposes and interstitial monitoring sensors must be tested annually along with the ATG console. Line leak detectors must also be tested annually along with line leak testing of the product lines. Shear valves mounted below the fuel dispenser must also be tested on an annual basis. All these UST parts can be tested by a licensed contractor. I have always recommended to clients to perform their annual walkthrough inspection simultaneously with licensed tester because the STP and UDC sumps must be accessed to perform the shear valve, leak detector, and line leak tests. You must maintain records of the ATG, ATG probes, interstitial monitoring sensors, shear valve, line leak, and leak detector tests for three years. These test records should be placed in your UST compliance paperwork and be readily accessible for a state inspector to view. Another important consideration is to ensure these tests are performed within 365-days of the previous test and not just done in the same month as the previous test. Typically, the licensed tester you use will have a schedule knowing when your site is due for these yearly tests, but it’s always a good idea to notify them at least one month in advance to ensure there are no scheduling conflicts interfering with your site being tested within the 365-day period.

Every state is obviously a little different but knowing the release reporting requirements and details is crucial to ensure compliance in the event of a release. For example, in my home state of Louisianna, if a possible release to the environment is discovered during the annual walkthrough inspection, you must notify the Louisiana Department of Environmental Quality (LDEQ) Singe Point of Contact (SPOC) within 24-hours of discovering the release at (225) 219-3640. If you discover an emergency situation, defined as any condition which could reasonably be expected to endanger the health and safety of the public, cause significant adverse impact to the land, water or air environment, or cause severe damage to property, you must immediately notify the Louisiana State Police Hazardous Material Hotline at (225) 925-6595. Once again, the take away is to know the specifics of your state agencies to ensure compliance.

Remember, you are only required to annually inspect your containment sumps and containment sump areas one time per year. However, inspecting these sumps more frequently could possibly discover a release before it adversely impacts the environment possibly costing you thousands of dollars in lost revenue and cleanup costs. You must also document your annual walkthrough inspection. You can create your own annual walkthrough inspection form or download one from the LDEQ website here. This inspection form should be kept with your UST compliance documents because if it is not documented, it did not happen. For any questions regarding your walkthrough inspection, or any other questions regarding UST compliance, feel free to reach out to me at scott.stamper@ppmco.com.